Silicon Nitride’s properties of high strength, superior fracture toughness, and heat retention provide a unique engineering material solution. These outstanding material properties make silicon nitride a suitable choice for use as components for Molten Aluminum Handling.

Components For Handling Molten ALuminum

Silicon Nitride’s properties of high strength, superior fracture toughness, and heat retention provide a unique engineering material solution. These outstanding material properties make silicon nitride a suitable choice for use as components for Molten Aluminum Handling.

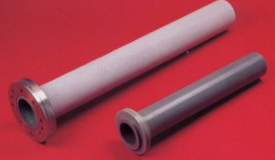

Silicon Nitride Components for Handling Molten Aluminum:

- Thermocouple Protection Tubes

Protection Tube Assemblies - L Type

- S Type

- Immersion Heater Tube

- Stalks for Low-Pressure Casting Machines

- Shot Sleeves for High-Pressure Die Casting

BENEFITS OF SILICON NITRIDE COMPONENTS FOR HANDLING MOLTEN ALUMINUM:

- Little or no contamination of molten aluminum

- Little or no corrosion from molten aluminum

- Little or no adherence of molten aluminum

- High strength remaining intact with the operating temperature of molten aluminum

- Excellent thermal insulation

- Reduce maintenance with increased service life